CORE ANALYSIS LABORATORY / RD&I

In line with Laser’s Quality policy, the Core Analysis/RD&I Laboratory’s vision is to be a reference centre known globally for tackling customized oil and gas challenges. To actualize this vision, the Laboratory’s activities are driven by the following quality objectives:

- To enhance the understanding of issues related to oil and gas production for clients.

- To acquire new knowledge applicable to the company’s business needs that eventually will result in new or improved products, processes, systems, or services.

Using standard methods with state-of-the-art equipment, our services are broadly categorized as:

- Routine Core Analysis

- CT scan of whole core

- Spectral Gamma Ray Log of whole core

- Whole core cutting (optional)

- Core Slabbing

- Core Plugging

- CT scan of plugs

- Digital photography (White Light – slabbed core and core plugs)

- Digital photograph (UV–slabbed core and core plugs)

- Sleeving (unconsolidated)

- Preservation of cores

- Lithological plug-hole description

- Plug cleaning and drying

- Grain density measurement

- Laser Particle Size Analysis

- Grain Size Analysis

- Solvent extraction by Dean-Stark method

- Porosity measurement at ambient and in-situ conditions

- Air permeability at ambient and in-situ conditions

- Detailed sedimentological description using Well CAD

- Report for Routine Core Analysis.

- Special Core Analysis

- Capillary pressure experiments

- Electrical properties tests

- Relative permeability measurements

- Wettability – Amott/USBM Combined

- Interfacial Tension (oil-brine, air-brine)

- Microstructure and petrography studies

- X-ray Diffraction (both sand and clay)

- Scanning Electron Microscopy (SEM)

- Thin section preparation and analysis

- Enhanced Oil Recovery

- Water Flooding

- Polymer Floading

- Surfactant Floading

- Minimum Miscibility Pressure (MMP)

Laser Engineering has expanded its services to embrace the Core Analysis Laboratory for the Oil and Gas industry in order to bridge the existing research gap in the country. She has invested in research and her laboratories can be used to conduct research in the following areas:

⦁ Enhanced Oil Recovery

⦁ Relative Permeability (Steady and Unsteady state)

⦁ Rock-Fluid Compatibility

⦁ Crude Oil Finger Printing

⦁ Complete Crude Assay Analysis

⦁ Flow Assurance

⦁ PVT Studies

⦁ Environmental Studies

⦁ Mineralogy Identification and Quantification (XRD and XRF)

Laser Engineering collaborates with private and government tertiary institutions of learning, research organizations and companies that are interested in conducting and developing in-country research capacity. Internally, the Core Analysis unit liaises with other units to conduct relevant studies in various areas that impact on the petroleum industry. The unit has published several research papers in reservoir management, PVT and Environmental studies.

The Core Analysis unit is also involved in software development especially for the oil and gas industry because software packages are part of the industry’s daily routine. A user-friendly software called LaserMBAL which can estimate hydrocarbon volumes and the primary drive energy of a reservoir has been developed. The snapshots below show some interfaces in the software.

An overview of our equipment and their uses are highlighted

X-Ray Diffractometer (Aeris Research edition)

It is used for mineralogical description of rock/sand sample. It identifies and quantifies minerals present in a rock samples.

Capillary Pressure Apparatus (PERMO-SCPS-2K)

It is used to measure the capillary pressure curve for multiple core plugs of various sizes at the same time within a broad range of pressure values (0-200 psi).

Auto Flood Reservoir Conditions Core Flooding System (AFS 300)

It is configured for core flooding experiments at reservoir conditions. Relative permeability experiments, EOR experiments (Chemical flooding, Miscible displacements & Thermal flooding), Wettability, Rock-fluid compatibility tests.

Automated Core Saturator System (M9160)

It ensures 100% saturation of core plugs with a

test fluid (Saturant).

Particle Size Analyzer (VariSifter Sonic Separator)

It is used for Particle Size Distribution Analysis (PSD).

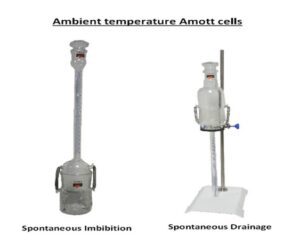

Amott cell for spontaneous imbibition and drainage tests. (Ambient temperature amott cell)

It is used to classify the wettability of a rock using The Amott–Harvey index.

XRD–Mill McCrone

It is used in pulverizing samples for subsequent XRD analysis.

Electrical property system (EPS 700)

It is used to measure

the electrical properties of core plugs. Formation Resistivity Factor (FRF), cementation exponent (m), Resistivity Index (RI) and Archie saturation exponent

(n). It also measures capillary pressure-saturation curves.

Surface Tension Meter (BZY-1 Automatic Surface Tension Meter)

It is used for surface tension measurements..

High Pressure Porosity and Permeability System (M9170)

It is used for porosity and permeability measurement of rock samples.

Slim tube (CoreLab 40ft slim tube coil)

It is used for multiple contact miscibility studies to determine the MMP and MMC to be used in EOR (miscible flooding).

COMPREHENSIVE CORE ANALYSIS SERVICES

Routine Core Analysis

Our routine core analysis provides fundamental insights into reservoir rock properties, delivering critical data for petroleum exploration and production. We systematically evaluate core samples to determine key characteristics including:

- Porosity measurements

- Grain density and bulk volume assessment

- Permeability assessments

- Lithology identification

- Saturations and fluid distributions

- Basic petrophysical properties

X-Ray Diffraction (XRD) Analysis

Utilizing advanced XRD technology, we deliver precise mineralogical characterization of reservoir rocks. Our services include:

- Detailed mineral composition identification

- Quantitative phase analysis

- Clay mineral assessment

- Structural and crystallographic insights

Special Core Analysis (SCAL)

Our advanced special core analysis goes beyond standard measurements, offering sophisticated characterization of reservoir rock behaviour. Our SCAL services include:

- Wettability determination

- Advanced relative permeability measurements

- Capillary pressure investigations

- Enhanced fluid-rock interaction analysis

- Enhanced oil recovery (EOR) potential evaluation

- Specialized reservoir rock performance evaluations

Each analysis is performed with precision instrumentation and expert geological interpretation, ensuring our clients receive robust, actionable reservoir intelligence.