.

WIRELINE / SLICKLINE OPERATIONS ON LAND, SWAMP & OFFSHORE

Slickline services play a vital role in oil and gas operations, offering tailored well-intervention solutions that utilize advanced, specialized wireline tools and equipment. The term ‘slickline’ describes a slender, single-strand wire – typically non-electric – that is meticulously deployed into the wellbore to execute a range of critical tasks and gather precise measurements, ultimately enhancing the efficiency and safety of oil and gas well operations.

DEFINITION

Slickline are single-strand, high strength non-electric cables lowered into oil and gas wells from the surface.

PURPOSE

Slickline services are mainly conducted to enhance, maintain, and diagnose well performance. These services utilize specialized tools and equipment that are deployed into the wellbore to carry out a range of tasks, including conducting bottom hole pressure surveys (BHP), setting or retrieving downhole safety valves, zone changes, sand bailing, well integrity test, gas lift operations, wax cutting, bottom hole sampling, plugging and unplugging, completion tasks (such as packing or tubing leak testing), fishing operation, swabbing.

OPERATIONS

Slickline Tools:

Slickline tools are a specialized category of equipment used during well workover and intervention activities in existing oil or gas production wells. These tools like running and pulling tools, electronic memory gauge , kickover tools, fishing tools, swabbing tools and other downhole tools are designed for efficient deployment, allowing them to be lowered into the wellbore via a steel strand wire connected to a wireline unit. This enables operators to perform various tasks within the well like unplugging, plugging, bottom hole pressure survey, SCSSV retrieval and installation, well integrity test, wax cutting, gas lift valve operation, zone change, swabbing, sand bailing, completion activities, fishing operations without the need for more invasive and complex methods.”

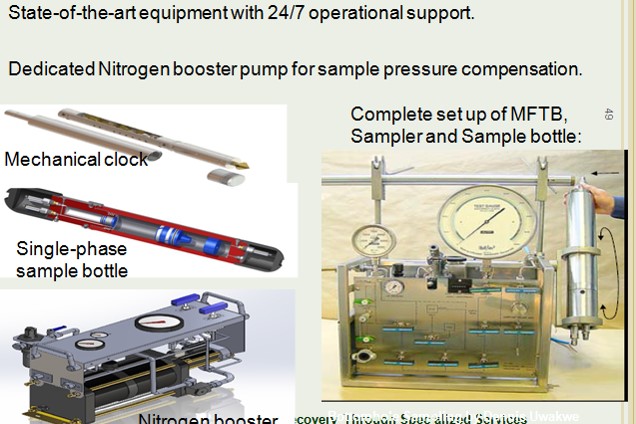

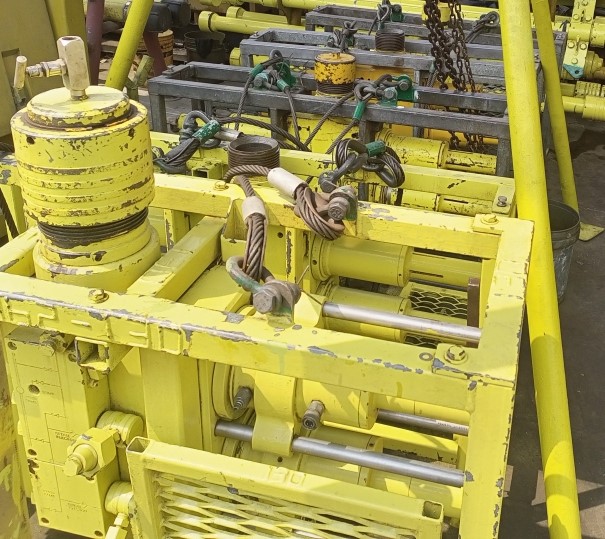

Our slickline operations contribute to setting new standards in the industry. Our state of the art equipment for services include rugged Slimline, Flyline and CS Skid unit(k winch) from ASEP of Holland which are zone 2 requirements, Bottom hole sampler, Slickline self loader PPS 28,PPS 25. Also, our software for analysis and interpretation are world class coupled with well experienced specialist.

Laser slickline services include

- Bottom Hole Pressure Surveys

- Gaslift valve Installation and Retrieval

- SCSSV Retrieval and Installation

- Well Integrity Test

- Wax Cutting

- Zone Change

- Swabbing

- Fishing Operation

- Plugging and Unplugging

- Sand Bailing

- Bottom Hole Sampling

- Completion

- Tool Rentals.

- Swamp Barge

BENEFITS

Cost Effective

Slickline services are typically faster and more cost-effective than other well intervention techniques, like hot oil operation, coiled tubing and workover rigs. They offer an economical solution for regular well maintenance, diagnostics, and optimization.

Minimal Well Disruption

Slickline operations can often be performed without the need to kill the well, which minimizes production downtime and maintains reservoir pressure.

Versatility

Slickline can be used for a variety of applications, including:

- Setting and retrieving downhole tools, such as plugs and gauges.

- Performing well diagnostics and monitoring production.

- Removing debris or obstructions from the wellbore.

The successful execution of slickline services hinges on the expertise of the personnel involved and strict adherence to safety protocols which is a top priority in Laser Engineering and Resource Consultant Limited. To ensure the safe and efficient execution of slickline operations, Laser operators undergo training and obtain relevant certifications.